nike

sportswear/lifestyle brand

All work done for Nike, was on behalf of Satis&fy, LLC.

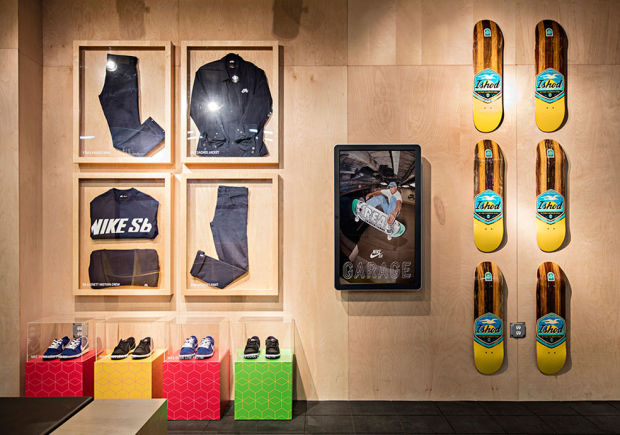

Nike SB Garage

Williamsburg, Brooklyn

Project Manager on behalf of satis&fy, llc.

work done: all production, maintenance of space, construction build, lighting, sound, permitting, custom creations, crew call, crew coordination, team management.

An old, empty car wash in Williamsburg was turned into the Nike SB skatepark known as the Garage. On behalf of satis&fy, I was in charge of the production, construction, and build of the space as Project Manager. Our mission was to take the client's design ideas and turning them into reality, all the while having to work alongside renowned skate park design company, California Skate. With no electricity, no lighting and with only 3 months to build before the launch, the pressure was on to satisfy the client. Having ensured all permitting and regulations were adhered to and all elemental structures would withstand the pounding of skateboards, the launch was a success.

http://nikesbgarage.com/#/

http://www.freshnessmag.com/2016/01/09/nike-sb-garage/

http://www.complex.com/sneakers/2016/01/nike-sb-garage-indoor-skatepark

http://www.nyskateboarding.com/2016/01/first-look-nike-sb-garage-2015

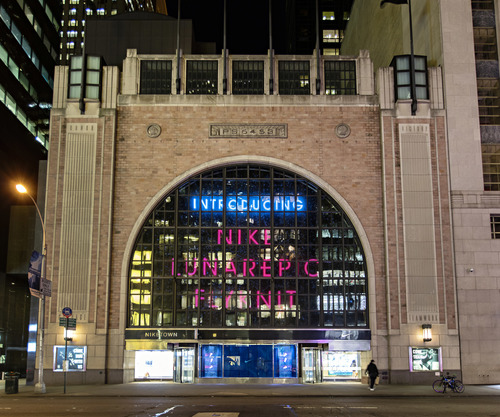

Nike Lunar Epic Activation

Niketown New York- Manhattan, new york

Project Manager on behalf of satis&fy, llc.

work done: all production, construction build, lighting, video, sound, custom creations, technical production, crew call, crew coordination, team management.

The first of 3 initiatives in a row, the Nike Lunar Epic Activation was the largest project to date for satis&fy. The design was whimsical, enchanting, and required a lot of pre production and planning. A customized high resolution LED wall was introduced to the center of Niketown. A lower resolution LED curtain was placed in the arching window to let passerby's know about the current activation. LED lights were important for this activation. LED strips were placed in panels along the walls, while LED lit shoes seem to float seamless on clear pegs. The floors were transformed into high gloss laminate floors while still preserving the foundation underneath. Clear shoe pedestals, made with a high plex was created to showcase the lunar epic shoes.

photos by Dorothy Hong

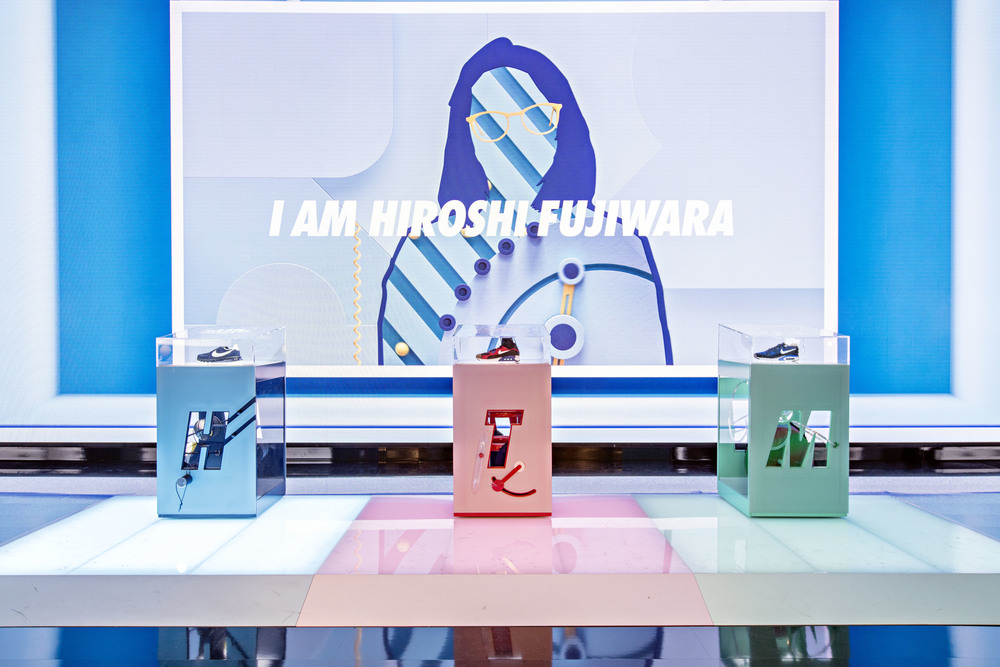

Nike Air Max Day

niketown new york- manhattan, new york

Project Manager on behalf of satis&fy, llc.

work done: all production, construction build, seamless transition, lighting, sound, video, custom creations, technical production, crew call, crew coordination, team management.

The next initiative after Lunar Epic at Niketown was Air Max Day where the storefront, tunnel, and the center of Niketown would be transformed into fun and playful colors that would portray the designers personalities. Custom LED lit platforms were built to house three different shoe pedestals while being sturdy enough to allow consumers to walk onto and experience the shoes. Each pedestal was fabricated to have moving parts that would continually wind themselves. The High Res LED wall was tested and color corrected to be able to handle the new vibrant colors. In the tunnel, milky panels with the three colors were different on both sides. On one side, an element on each designer would have a moving trinket. On the other side, a clear plexi glass would be placed in front of the milk panels to showcase different inspirational gadgets that inspired each designer.

photos by Dorothy Hong

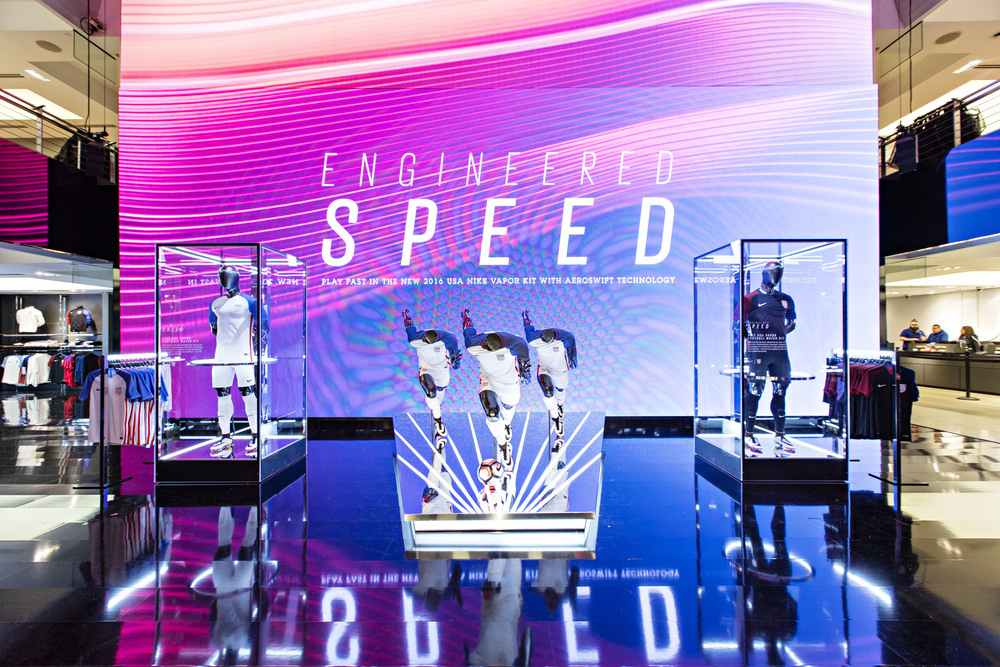

Nike National Team Kit

niketown new york- manhattan, new york

Project Manager on behalf of satis&fy, llc.

work done: all production, construction build, lighting, sound, video, custom creations, technical production, crew call, crew coordination, team management.

For the 3rd and final Nike initiative at Niketown New York, the transition from Air Max Day to National Team Kit was the frosting on the final layer of the cake. Transforming the colorful AMD to NTK proved challenging as issues of seamless transition during overnights poised an issue. However, leading the charge of the project we were able to execute to the client's expectations and then some.

The Nike mannequins needed to be dipped in chrome to give the look of stealth and strength. The tunnel walls were replaced with LED moving gradient lights. The mannequin displays house moving technical pieces that needed to be fully capable of functioning on its own. Large seamless graphics needed to be produced to cover the center walls, but sturdy enough to withstand consumers on a daily basis. Custom made chrome pedestals with LED inserts were created and was strong enough to place a very heavy Nike body form on top. The technical and video team had to recallibrate the High Res LED wall for the new National Team Kit video.

photos by Dorothy Hong